Particle Deposition using inkjet technology prints layers of material in the form of individual drops. With laminated object manufacturing (LOM), thin layers are cut to shape and joined (e.g., paper, polymer, metal). selective laser melting (SLM) or direct metal laser sintering (DMLS), selective laser sintering (SLS), fused deposition modeling (FDM), or fused filament fabrication (FFF), while others cure liquid materials using different sophisticated technologies, such as stereolithography (SLA). Some methods melt or soften the material to produce the layers, for example. The main differences between processes are in the way layers are deposited to create parts and in the materials that are used. Ī large number of additive processes are now available. The printers were originally large, expensive, and highly limited in what they could produce. Several 3D printing processes have been invented since the late 1970s. Some printers are large enough to fabricate buildings whilst others tend to micro and nanoscale sized objects and in general many different technologies can be exploited to physically produce the designed objects. Some lend themselves better toward industry use (in this case the term Additive Manufacturing is preferred) whereas others make 3D printing accessible to the average consumer. The variety of processes and equipment allows for numerous uses by amateurs and professionals alike. These usually involve aspects such as speed, costs, versatility with respect to feedstock material, geometrical limitations and tolerances, as well as a mechanical and appearance properties of the products such as strength, texture and color. There are many different 3D printing processes, that can be grouped into seven categories: Įach process and piece of equipment has pros and cons associated with it.

Some of the different types of physical transformations which are used in 3D printing include melt extrusion, light polymerization, continuous liquid interface production and sintering. 3D printing is also known as additive manufacturing, therefore the numerous available 3D printing process tend to be additive in nature with a few key differences in the technologies and the materials used in this process.

3D scanning is a process of collecting digital data on the shape and appearance of a real object, creating a digital model based on it.Ī variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing.

_5lpomK8.jpg)

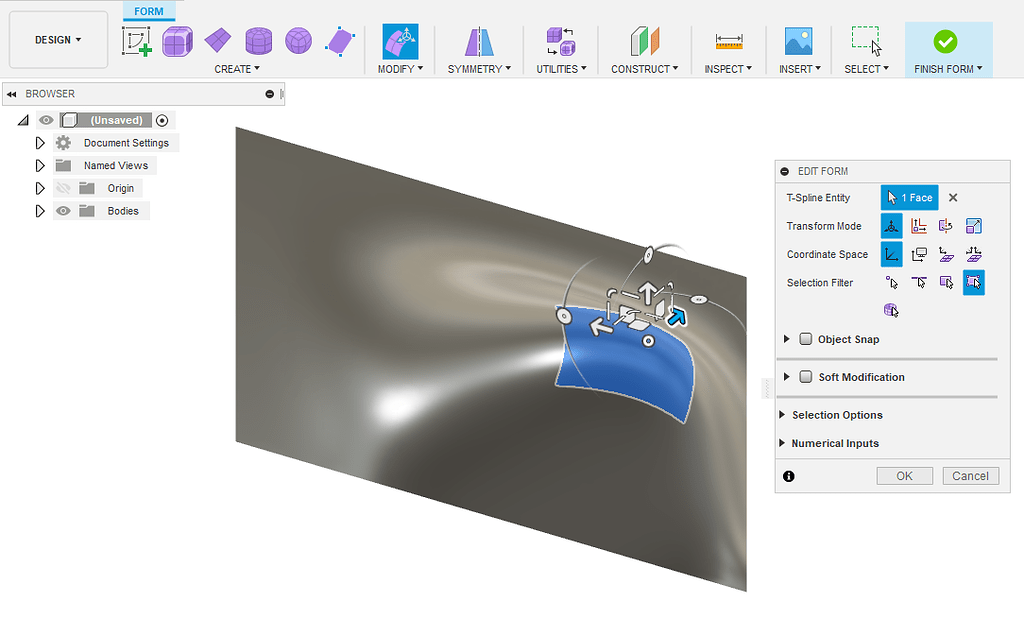

The manual modeling process of preparing geometric data for 3D computer graphics is similar to plastic arts such as sculpting. Computer-Aided Design (CAD) model used for 3D printing.

0 kommentar(er)

0 kommentar(er)